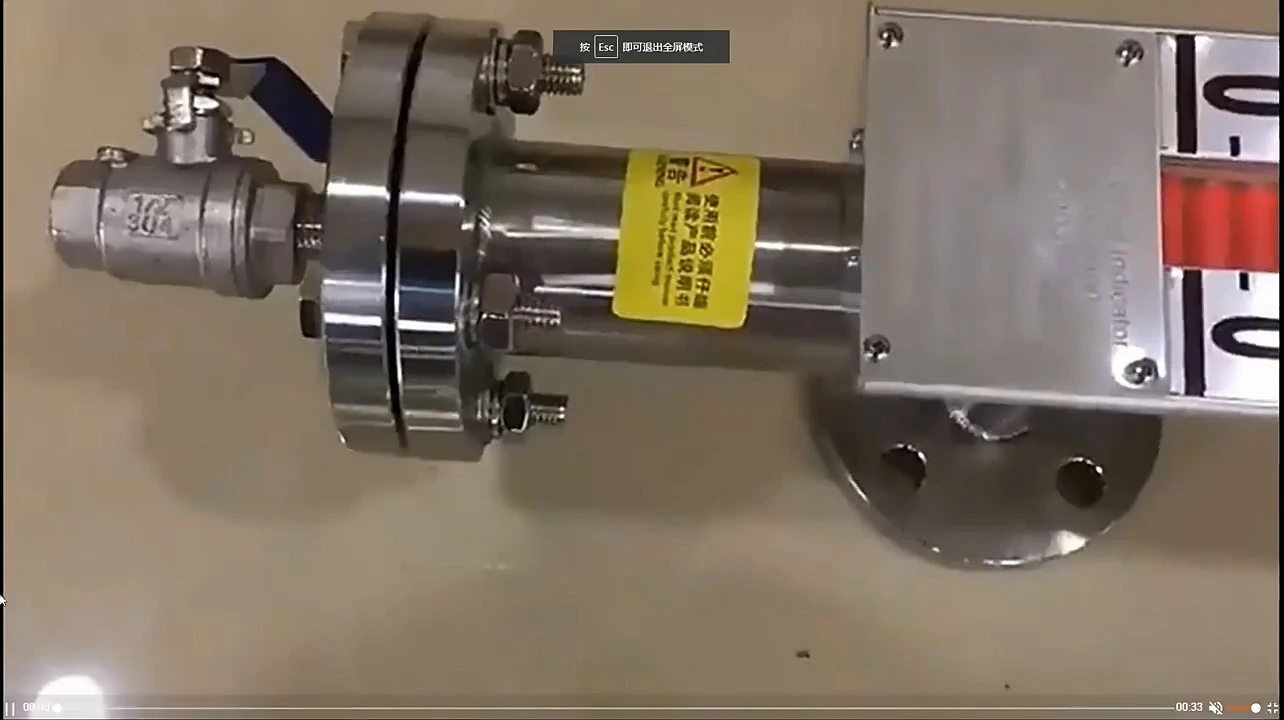

The Top Sales Production Easy Catch Mechanical Fuel Level Gauge

Place of Origin: Shanghai, China

Customized support: OEM, ODM, OBM

Brand Name: GN

Model Number: CX-MLM

Test Range: 300~15000mm

Work temperature: -20~150C of magnetic level gauge

Work pressure: 0~9.6Mpa of oil level gauge

Density: 0.5~2 of mechanical fuel level gauge

Material: stainless steel and PP; PE

Installation: Side mounted; Top mounted; Bottom mounted

Alarm: Top and low alarm

Color: Red and white

Display: mechanical display

Accuracy: 5mm

CX-MLM

Magnetic Level Gauge

Magnetic level gauge application developed from based on the principle of buoyancy and magnetic coupling. When the measured level in the container movements, the dominant tube level gauge also will lift the float, the permanent magnet inside the float is transferred to the magnetic level indicator by magnetic field coupling, driving the red, white turned columns flip 180 degrees, when when the liquid level rises, the column turned from white to red when the level drops, the column turned from red to white, pointer red, white circles located at the medium level of the actual height of the container, in order to achieve the level instructions.

Magnetic level gauge electrical signal is implemented by a combination of remote and basic level remote device. Level remote device by the UR-type resistance sensors and UB type R / I converter modules, the transmitter sensor in the form of bundled fixed to the outside of the main conduit UHZ type level gauge magnetic flap so that it is level count the same magnetic coupling system. When the magnetic float moves up and down with the liquid level, the level corresponding to the position of the reed that is the role of the magnetic field inside the float pull resistor chain resistance to change by switching module will change the resistance signal into a standard two-wire 4 ~ 20mADC output signal, the signal can be easily and III-type electric instrument, display instrument supporting the use, can also be indicative of the light beam, the digital display regulator supporting the use of alarm, so as to display, control, regulation and alarm purposes.

Product Parameters

|

CX- |

Shanghai Cixi |

|

MLM- |

Magnetic level meter |

|

Range (M) |

1, 2, 3 |

|

Material |

M1-SS304 |

|

M2-SS316L |

|

|

M3-UPVC |

|

|

M4-UPP |

|

|

M5-PTFE |

|

|

Output |

4 - |

|

AH-upper alarm |

|

|

AL-lower alarm |

|

|

AHL-upper and lower alarm |

|

|

Installation |

S-side-mounted |

|

T-Top-mounted |

|

|

B-Bottom-mounted |

|

|

Sensor temperature |

N-10-200 Celsius degree |

|

H-High temperature-10-350 |

|

Type |

Wet Material |

Measuring Range (mm) |

Data of liquid |

|||

|

Temp |

Pressure |

Density |

Viscosity |

|||

|

Standard |

304 |

300-8000 |

-20~150 |

0-2.45 |

0.5-2 |

<=0.04 |

|

H-pressure |

300-8000 |

-20~150 |

2.45-9.6 |

0.5-2 |

<=0.04 |

|

|

H-temp |

300-8000 |

-20~350 |

2.45-9.6 |

0.5-2 |

<=0.04 |

|

|

Low-tem |

300-3500 |

>-40 |

0-2.45 |

0.5-2 |

<=0.04 |

|

|

LPG |

300-15000 |

-20~150 |

0-2.45 |

0.45-0.7 |

<=0.05 |

|

|

Corrosio-proof |

316L |

300-8000 |

-20~150 |

0-2.45 |

0.5-2 |

<=0.04 |

|

Corrrossion-poof |

PP |

300-5000 |

20~100 |

0-0.6 |

0.5-2 |

<=0.04 |

|

Corrrossion-poof |

U-PVC |

300-5000 |

20~60 |

0-0.5 |

0.5-2 |

<=0.04 |

|

Corrrossion-poof |

ABS. |

300-5000 |

-20~120 |

0-0.6 |

0.5-2 |

<=0.04 |

|

Corrrossion-poof |

316 pipe PP liner |

300-15000 |

-20~100 |

0-1.0 |

0.5-2 |

<=0.04 |

|

Corrrossion-poof |

PE |

300-5000 |

20~40 |

0-0.6 |

0.5-2 |

<=0.04 |

|

warming type |

304 |

300-15000 |

-20~150 |

0-2.45 |

0.5-2 |

<=0.05 |

|

H-viscosity |

304 |

300-15000 |

-20~150 |

0-2.45 |

0.5-2 |

<=0.05 |

|

sanitary |

304. |

300-15000 |

-.20~150 |

0-1.6 |

0.5-2 |

<=0.05. |

Product Details