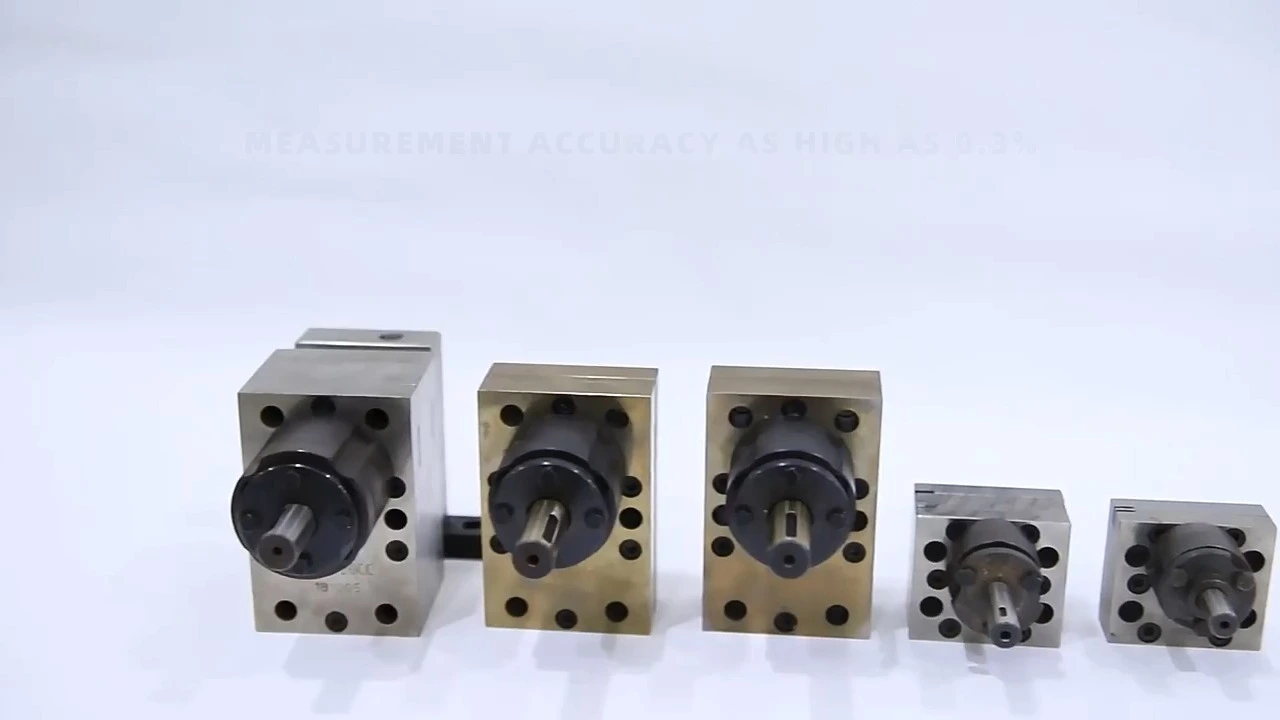

High Viscosity Polyurethane Silicone Metering Pump Epoxy Resin Hot Melt Glue Dosing Chemical Spinning Resin Gear Metering Pump for Extruder

Place of Origin: Shanghai, China (Mainland)

Brand Name: GN

Model Number: CX-GWMP

Structure: Gear Pump

Usage: metering

Application: Metering

Power: Electric

Fuel: liquid

Pressure: High Pressure

CX-GWMP

Gear Metering Pump

The design utilizes high standard external spur gears enclosed within a close tolerance housing assembly. This provides you the precise volume of fluid dispensed per shaft revolution. The housing is constructed from a precision ground and lapped three-plate assembly. This assembly is aligned with dowels to allow close control of operating clearances. This construction method in combination with several proprietary internal features is what ensures precise, pulseless and reliable flow under varying process conditions.

When CIXI Instrument pumps are coupled with a pre-packaged, integrated, closed-loop speed control and a compact motor driver assembly (AC or DC), CIXI Instrument is able to provide the most precise and flexible metering gear pump system on the market.

Product Parameters

The High Quality And Hard Steel Material Dosing Gear Metering Pump

|

Min inlet pressure |

<0.2Mpa |

|

Max outlet pressure |

<8Mpa |

|

Working speed |

5~200 R/min |

|

Medium |

Fluid |

|

Temperature |

200℃ |

|

Flow capacity |

6-200CC/R or 0.05~3.6cc/r |

|

Material |

Hard steel/Stainless Steel |

|

Accuracy |

1.0% |

|

Standard or Nonstandard |

Standard |

|

Supply Ability |

|

|

Supply Ability |

1000 Piece/Pieces per Month of meter pump |

|

Packaging & Delivery |

|

|

Packaging Details |

Carton box of pump |

|

Port |

Shanghai |

|

Model |

Displacement |

Total Height |

Base Height |

Min Inlet Pressure |

Max Outpet Pressure |

Accuracy |

Temperature |

|

(CC/R) |

|||||||

|

GWMP-0.15 |

0.15 |

83 |

28.1 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-0.3 |

0.3 |

85 |

30.2 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-0.6 |

0.6 |

85 |

32 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-1.2 |

1.2 |

90 |

34 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-2.4 |

2.4 |

100 |

42 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-3.6 |

3.6 |

105 |

50 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-6 |

6 |

130 |

41 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-9 |

9 |

135 |

46 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-12 |

12 |

140 |

51 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-15 |

15 |

145 |

56 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-20 |

20 |

150 |

64 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-30 |

30 |

165 |

80 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-40 |

40 |

90 |

215 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-50 |

50 |

97 |

215 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-60 |

60 |

104.5 |

230 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-75 |

75 |

112 |

230 |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-80 |

80 |

Customized |

Customized |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

|

GWMP-125 |

125 |

Customized |

Customized |

<0.2Mpa |

<30Mpa |

+/-3% |

200℃ |

Note: Direction of rotation: clockwise from the axis of rotation

Product Details

Production instructions