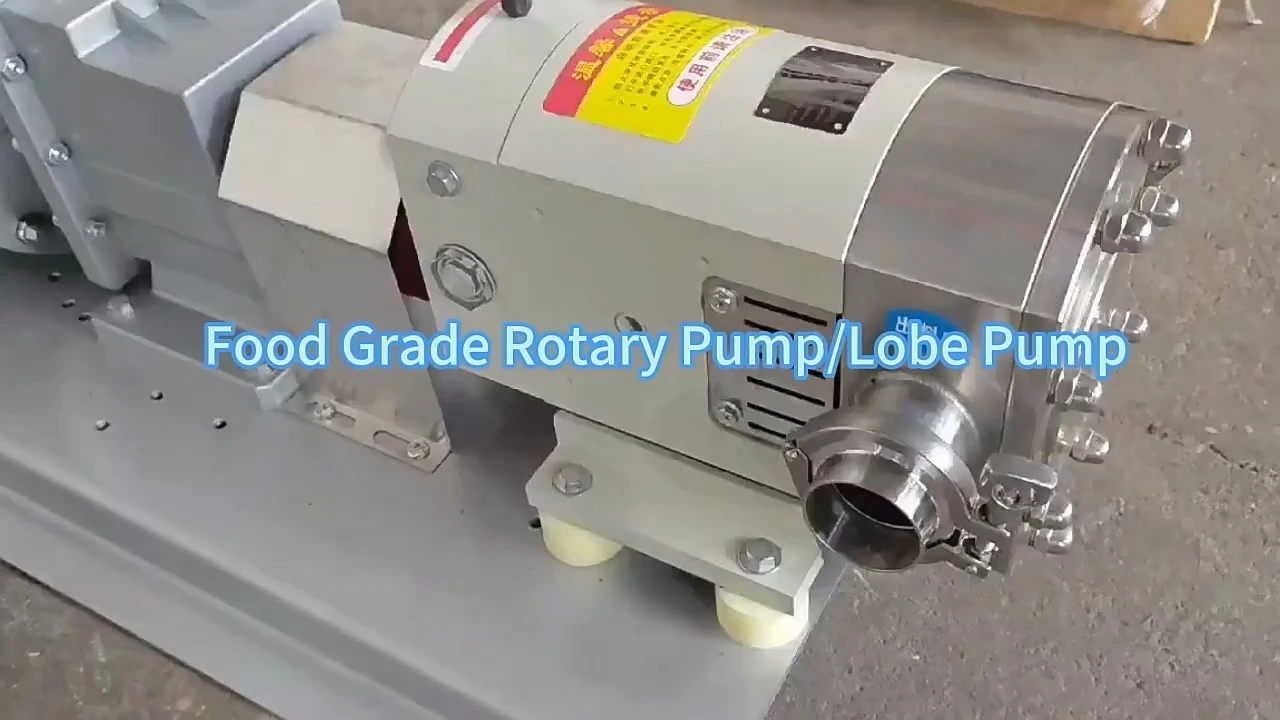

Stainless steel rotor pump lobe pump for hygienic processes/ transfer high viscosity material

Place of Origin: Shanghai, China

Customized support: OEM, ODM, OBM, Software re-engineering

Power Source: Electric

Structure: Multistage Pump

Warranty: 3 years

Brand Name: GN

Model Number: CX-NYP

Horse power: customized

Cable Length: customized

Outlet Size: DN25~DN150

Power: 0.75KW~22KW

Product name: High viscosity rotor pump

Application: Liquid Transfer

Usage: Transfer High Viscosity Liquid

Material: Stainless Steel

Keywords: Liquid Transfer Pump

Type: Self-priming Centrifugal Pump

Feature: High Efficiency

Fuel: AC Electric Induction Motor

Function: Transport Liquid

Pump Type: Suctin Pump

CX-NYP

Rotor pump

NYP high viscosity rotor pump is a delivery pump for high viscosity media. It is suitable for the transportation industry of various fluids, especially for fluid transportation that handles large changes in viscosity and a wide range. It can be used for transportation in petroleum, chemical industry, paint, grease, medicine, dye and food industries. There are two types of materials: ordinary cast iron and stainless steel. The pump head, pump casing and sealing cavity can all be equipped with insulation jackets. Select the location where insulation is required based on actual needs. The jacket and the pump body are cast into one body, which has good thermal insulation effect and can avoid various problems caused by welding the jacket.

When heating is required, various heating media such as hot steam and thermal oil can be passed into the jacket cavity for heat preservation. When cooling is required: the constant temperature of the pump body can be maintained through various coolants. Adjustable clearance: The pump can adjust the gear clearance according to the viscosity needs without disassembling the pump to meet the process requirements of the pump under different viscosities. The operation is simple and does not require disassembly of pump parts. The outer rotor drives the inner rotor to rotate in the same direction, resulting in less wear and long service life.

Product Parameters

|

Titles |

Technical Specifications |

|

Product Name |

High Viscosity Sanitary Rotor Lobe Pump Sugar Syrup Fluid Transfer Pumps Positive Displacement Rotor Gear Pump |

|

Description |

Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosmetics and industries. |

|

Construction |

Horizontal Ace series, diffirent rotor shapes(single rotro,tri-lobe rotors and butterfly type rotors) |

|

Material |

SS304/SS316 |

|

Seal Material |

EPDM (Standard, approval) |

|

Temperature type |

-10 to 180℃ |

|

Max. Flow: |

43000Liter/h |

|

Motor Power |

0.37KW~22KW |

|

Voltage |

220V,380V(110-480v) |

|

Max.pressure: |

10bar |

|

Motor |

ABB, Siemens,Our Domestic Brand,50hz/ 60hz |

|

Surface treatment |

Inner polished and Sandblast outside |

|

Connection |

Max. 1000m (If >1000m,customized) |

|

Application Scope |

Clamp, Thread, weld, Flange |

|

Availably standard |

DIN, SMS, 3A, RJT, ISO/IDF |

|

Application scope |

Dairy, food, beverage, pharmacy, cosmetic, etc |

| Type | Reference range | Pressure Range |

Speed rpm |

Power (KW) |

Caliber (mm) |

||

| L/100r | m³/h | L/h | (Mpa) | ||||

| J LX-6 | 6 | 1.4 | 1400 | 0~0.4 | 10~400 | 0.75 | 25 |

| JLX-9 | 9 | 2.1 | 2100 | 0~0.4 | 10~400 | 1.1 | 32 |

| J LX-18 | 18 | 4.3 | 4300 | 0~0.6 | 10~400 | 1.5 | 40 |

| J LX-36 | 36 | 6.9 | 6900 | 0~0.6 | 10~400 | 2.2 | 50 |

| J LX-60 | 60 | 8.6 | 8600 | 0~0.6 | 10~400 | 4 | 65 |

| J LX-105 | 105 | 25 | 25000 | 0~1.0 | 10~40 | 7.5 | 80 |

| J LX-180 | 180 | 43.1 | 43100 | 0^1.0 | 10~400 | 11 | 100 |

| J LX-250 | 250 | 60 | 60000 | 0~1.0 | 10~400 | 15 | 125 |

| J LX-325 | 325 | 78 | 78000 | 0~1.0 | 10~400 | 18.5 | 150 |

| J LX-535 | 535 | 127.5 | 127500 | 0~1.0 | 10~400 | 18.5 | 150 |

| J LX-700 | 700 | 167.5 | 167500 | 0^1.0 | 10~400 | 18.5 | 200 |

Product Details