Unlocking The Benefits Of A Magnetic Liquid Level Gauge

Are you looking for an efficient and reliable solution to monitor liquid levels in your industrial processes? Look no further than a magnetic liquid level gauge. In this article, we will delve into the various benefits and advantages of utilizing this innovative technology. From its precision measurement capabilities to its user-friendly design, discover how unlocking the potential of a magnetic liquid level gauge can streamline your operations and enhance productivity. Read on to learn more about this cutting-edge instrument and revolutionize the way you monitor liquid levels.

- Introduction to Magnetic Liquid Level Gauges

to Magnetic Liquid Level Gauges

Magnetic liquid level gauges are innovative devices that provide accurate and reliable measurement of liquid levels in various industrial applications. These gauges utilize the principles of magnetism to provide real-time monitoring of liquid levels, offering numerous benefits over traditional methods of level measurement. In this article, we will delve into the features and advantages of magnetic liquid level gauges, as well as their applications in different industries.

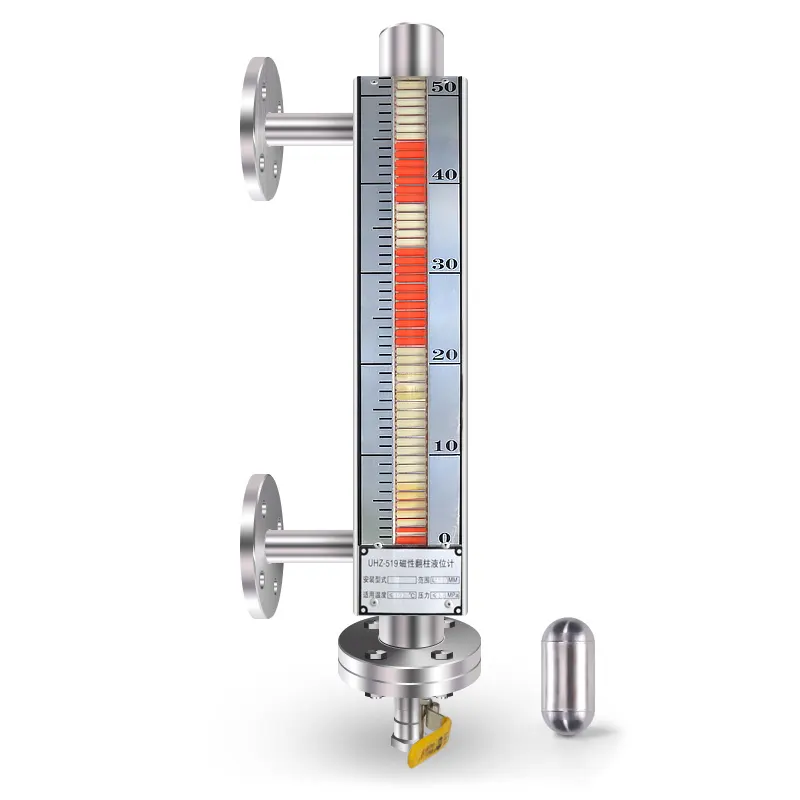

One of the key advantages of magnetic liquid level gauges is their simplicity and ease of use. These gauges consist of a float containing a magnet that moves up and down along a guide tube. As the liquid level changes, the float moves accordingly, causing the magnetic field to fluctuate. This change in magnetic field is detected by a sensor installed outside the guide tube, which provides a continuous reading of the liquid level. This simple design eliminates the need for complex wiring or calibration, making installation and maintenance a breeze.

Furthermore, magnetic liquid level gauges are highly versatile and can be customized to suit different types of liquids and operating conditions. The float can be made of various materials, such as stainless steel or plastic, depending on the compatibility with the liquid being measured. In addition, the guide tube can be constructed from different materials, such as glass or metal, to withstand corrosive or high-pressure environments. With a wide range of options available, magnetic liquid level gauges can be tailored to meet the specific requirements of any application.

Another significant benefit of magnetic liquid level gauges is their accuracy and reliability. Unlike traditional sight glass or level sensors, magnetic gauges provide continuous and precise measurements of liquid levels, with minimal risk of error or malfunction. The non-contact operation of these gauges also eliminates the risk of contamination or leakage, ensuring a safe and efficient monitoring system. This high level of accuracy makes magnetic liquid level gauges ideal for critical processes where precise measurement is essential.

In terms of applications, magnetic liquid level gauges find widespread use in industries such as petrochemical, pharmaceutical, food and beverage, and water treatment. These gauges are commonly used in storage tanks, reactors, pipelines, and other vessels to monitor the level of liquids such as chemicals, fuels, oils, and water. The ability to withstand harsh environments and provide reliable performance makes magnetic liquid level gauges a preferred choice for industries that prioritize safety, efficiency, and accuracy in their operations.

In conclusion, magnetic liquid level gauges offer a wealth of benefits that make them a valuable tool for liquid level measurement in industrial settings. From their simple yet effective design to their versatility and accuracy, these gauges provide a reliable solution for monitoring liquid levels in a wide range of applications. Whether used in chemical processing plants, pharmaceutical facilities, or water treatment facilities, magnetic liquid level gauges offer a cost-effective and efficient way to ensure optimal performance and safety. By understanding the features and advantages of magnetic liquid level gauges, industries can unlock their full potential and reap the benefits of accurate and reliable liquid level measurement.

- How Magnetic Liquid Level Gauges Work

A magnetic liquid level gauge is a crucial instrument used in various industries such as oil and gas, chemical, pharmaceutical, and food processing. This article will delve into the intricate workings of magnetic liquid level gauges and explore the benefits they offer to businesses.

At its core, a magnetic liquid level gauge utilizes the principles of magnetism to accurately measure the level of liquid in a container. The gauge consists of a float with a magnetic strip attached to it, which moves up and down within a chamber as the liquid level changes. Outside the chamber, there is a series of magnetic switches or sensors that are triggered by the movement of the float. These sensors then send signals to a display unit, which indicates the precise level of the liquid.

One of the key advantages of magnetic liquid level gauges is their accuracy. Unlike traditional sight glass gauges, which can be prone to errors and inaccuracies, magnetic liquid level gauges provide precise and reliable readings. This is especially important in industries where precise measurement of liquid levels is critical for safety and efficiency.

Another benefit of magnetic liquid level gauges is their versatility. They can be used to measure the level of a wide range of liquids, including corrosive chemicals, high-temperature substances, and opaque fluids. This versatility makes them suitable for a variety of applications and industries.

Furthermore, magnetic liquid level gauges are low maintenance and easy to install. They do not require frequent calibration or adjustment, saving time and labor costs for businesses. Additionally, their simple design means they are less prone to malfunctions or breakdowns, ensuring uninterrupted operation.

In terms of safety, magnetic liquid level gauges offer several advantages. Since the gauge itself is installed outside the container, there is no risk of leakage or contamination of the liquid. This reduces the potential for accidents and ensures a safe working environment for employees.

Overall, magnetic liquid level gauges are a cost-effective and reliable solution for businesses looking to accurately measure liquid levels. With their accuracy, versatility, low maintenance, and safety benefits, they are an invaluable tool for industries where precise measurement of liquid levels is essential.

In conclusion, the benefits of a magnetic liquid level gauge are numerous and can greatly enhance the efficiency and safety of industrial processes. By understanding how these gauges work and the advantages they offer, businesses can unlock their full potential and streamline their operations.

- Advantages of Using Magnetic Liquid Level Gauges

A magnetic liquid level gauge is a versatile and reliable tool for monitoring the level of liquids in various industrial applications. This instrument utilizes the principles of magnetism to provide accurate and real-time measurements, making it a preferred choice for many industries. In this article, we will explore the advantages of using a magnetic liquid level gauge and how it can benefit your operations.

One of the main advantages of a magnetic liquid level gauge is its accuracy. Unlike traditional methods of level measurement, such as sight glasses or float switches, magnetic liquid level gauges provide precise and reliable readings. This is because they are not affected by factors such as temperature, pressure, or the properties of the liquid being measured. The use of magnets ensures that the level measurement remains consistent, even in harsh operating conditions.

Another benefit of a magnetic liquid level gauge is its durability. These instruments are designed to withstand extreme temperatures, pressures, and corrosive environments, making them suitable for a wide range of applications. The robust construction of the gauge ensures long-term reliability and minimal maintenance requirements, saving time and money in the long run.

Furthermore, magnetic liquid level gauges are easy to install and use. With their simple design and straightforward operation, they can be quickly set up and integrated into existing systems. This ease of use makes them ideal for applications where rapid and accurate level monitoring is essential.

In addition to their accuracy, durability, and ease of use, magnetic liquid level gauges offer versatility. They can be used in various industries, including oil and gas, chemical processing, water treatment, and food and beverage production. Whether you need to measure the level of liquids in a storage tank, reactor, or pipeline, a magnetic liquid level gauge can provide reliable and consistent readings.

Overall, the benefits of using a magnetic liquid level gauge are clear. From its accuracy and durability to its ease of installation and versatility, this instrument offers a reliable solution for monitoring liquid levels in a wide range of industrial applications. If you are looking to improve the efficiency and safety of your operations, consider investing in a magnetic liquid level gauge today.

- Applications of Magnetic Liquid Level Gauges

Magnetic liquid level gauges have become an integral part of industrial processes and applications due to their reliability, accuracy, and ease of use. These innovative devices use magnetic principles to accurately measure the level of liquid in a tank or vessel, making them indispensable in various industries such as oil and gas, chemical, pharmaceutical, and food and beverage.

One of the key applications of magnetic liquid level gauges is in the oil and gas industry, where they are used to monitor the level of crude oil, refined products, and various chemicals in storage tanks. These gauges provide real-time data on the level of liquid, allowing operators to closely monitor inventory levels and prevent overfilling or underfilling. This not only ensures operational efficiency but also helps in preventing spills and accidents, thereby enhancing safety and environmental compliance.

In the chemical industry, magnetic liquid level gauges are used to monitor the levels of corrosive and hazardous chemicals in storage tanks. The non-contact measurement principle of these gauges makes them ideal for such applications, as they eliminate the risk of chemical exposure and contamination. Additionally, the robust construction of magnetic liquid level gauges ensures long-term reliability and durability, even in harsh chemical environments.

The pharmaceutical industry also benefits from the use of magnetic liquid level gauges, where they are used to monitor the levels of various liquids and solvents in manufacturing processes. These gauges provide accurate and reliable data, ensuring the quality and consistency of pharmaceutical products. Moreover, the hygienic design of magnetic liquid level gauges makes them suitable for use in cleanroom environments, where strict cleanliness and contamination control are essential.

In the food and beverage industry, magnetic liquid level gauges are used to monitor the levels of liquids such as water, milk, juices, and other beverages in storage tanks and processing equipment. The sanitary design of these gauges complies with food safety regulations and allows for easy cleaning and maintenance. This ensures the integrity and quality of food and beverage products, while also improving operational efficiency and preventing downtime.

Overall, the applications of magnetic liquid level gauges are vast and varied, making them indispensable in a wide range of industries. Their accurate and reliable performance, along with their ease of installation and maintenance, make them a cost-effective and efficient solution for monitoring liquid levels in tanks and vessels. With ongoing advancements in technology and design, magnetic liquid level gauges continue to unlock new benefits and possibilities for industries around the world.

- Tips for Proper Installation and Maintenance of Magnetic Liquid Level Gauges

Unlocking the Benefits of a Magnetic Liquid Level Gauge - Tips for Proper Installation and Maintenance of Magnetic Liquid Level Gauges

A magnetic liquid level gauge is a crucial instrument used in various industries to accurately measure the levels of liquids in tanks or vessels. This innovative technology utilizes magnetic coupling to provide reliable and accurate readings, making it a popular choice for many applications. However, to fully unlock the benefits of a magnetic liquid level gauge, proper installation and maintenance are essential.

Installation of a magnetic liquid level gauge requires careful planning and attention to detail. Before installation, it is important to determine the appropriate location for the gauge on the tank or vessel. The gauge should be placed in a position where it can provide a clear and unobstructed view of the liquid level. Additionally, the gauge should be mounted securely to prevent any movement or vibrations that could affect its accuracy.

When installing a magnetic liquid level gauge, it is crucial to follow the manufacturer's guidelines and recommendations. This includes ensuring that the gauge is properly calibrated and adjusted according to the specific requirements of the application. Proper calibration is essential for ensuring accurate and reliable readings, so it is important to pay close attention to this step during installation.

In addition to proper installation, regular maintenance is also key to maximizing the benefits of a magnetic liquid level gauge. Maintenance tasks for a magnetic liquid level gauge typically include checking for any signs of wear or damage, cleaning the gauge regularly to remove any build-up or debris, and ensuring that all components are functioning properly.

One of the main benefits of a magnetic liquid level gauge is its reliability and accuracy. By properly installing and maintaining the gauge, users can ensure that they are getting accurate and precise readings of the liquid levels in their tanks or vessels. This can help prevent overfilling or underfilling of tanks, which can lead to costly and potentially dangerous consequences.

Another benefit of a magnetic liquid level gauge is its ease of use. With its simple design and straightforward operation, a magnetic liquid level gauge is easy to read and interpret, making it a valuable tool for operators and maintenance personnel. Additionally, the gauge is durable and resistant to harsh operating conditions, making it suitable for a wide range of applications.

Overall, a magnetic liquid level gauge is a valuable instrument that can provide accurate and reliable measurements of liquid levels in tanks or vessels. By following proper installation and maintenance procedures, users can unlock the full benefits of this technology and ensure optimal performance for years to come.

Conclusion

In conclusion, the magnetic liquid level gauge is a valuable tool that offers numerous benefits across various industries. From its accuracy and reliability to its ease of installation and maintenance, this device provides a practical solution for monitoring liquid levels. By utilizing the innovative technology of magnetic coupling, it ensures accurate and real-time data that can be crucial for ensuring operational efficiency and safety. Whether in a chemical plant, food processing facility, or wastewater treatment plant, the magnetic liquid level gauge is a versatile and cost-effective option for businesses looking to optimize their processes. Embracing this technology can help unlock a range of benefits, ultimately leading to improved productivity and cost savings. Upgrade your liquid level monitoring system today and experience the advantages of a magnetic liquid level gauge firsthand.