Exploring The Accuracy And Benefits Of A High-Level Magnetic Gauge

Are you interested in learning about cutting-edge technology that can revolutionize the way measurements are taken in various industries? Look no further than our article on exploring the accuracy and benefits of a high-level magnetic gauge. Discover how this innovative tool can provide precise measurements and streamline processes, saving time and improving efficiency. Join us as we delve into the world of magnetic gauges and explore the endless possibilities they offer.

- An Introduction to High-Level Magnetic Gauges

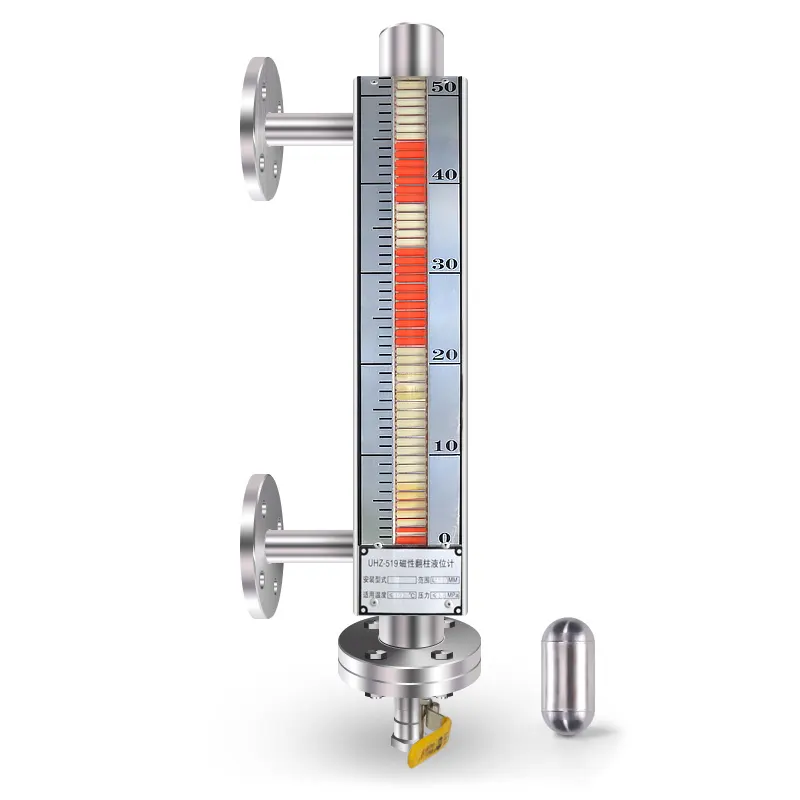

High-level magnetic gauges have revolutionized the way in which measurements are taken in various industries. These advanced devices offer unparalleled accuracy and precision, making them essential tools for professionals who require precise measurements in their work. In this article, we will explore the accuracy and benefits of high-level magnetic gauges, providing an introduction to their functionality and applications.

One of the key features of high-level magnetic gauges is their ability to provide highly accurate measurements. Unlike traditional gauges, which rely on manual readings that can be prone to human error, high-level magnetic gauges use magnetic technology to ensure precise and reliable measurements. This technology allows the gauge to directly sense the level of a liquid or material, providing an accurate reading without the need for manual intervention.

In addition to their accuracy, high-level magnetic gauges offer a range of benefits that make them indispensable tools in a variety of industries. One of the main advantages of these gauges is their versatility. They can be used to measure the level of liquids, solids, and powders, making them suitable for a wide range of applications. From monitoring the level of fuel in a tank to measuring the volume of material in a silo, high-level magnetic gauges can be used in diverse environments to ensure accurate and reliable measurements.

Furthermore, high-level magnetic gauges are incredibly easy to use, making them accessible to professionals of all levels of experience. With their simple design and user-friendly interface, these gauges can be quickly set up and calibrated, allowing users to start taking measurements with minimal training. This ease of use not only saves time but also reduces the risk of errors, ensuring that measurements are consistently accurate.

Another key benefit of high-level magnetic gauges is their durability and reliability. These gauges are built to withstand harsh conditions, making them ideal for use in industrial environments where they may be exposed to extreme temperatures, chemicals, or physical stress. Their robust construction and high-quality materials ensure that they can provide accurate measurements consistently over time, without the need for frequent maintenance or replacement.

Overall, high-level magnetic gauges are essential tools for professionals who require precise measurements in their work. With their accuracy, versatility, ease of use, and durability, these gauges offer a range of benefits that make them indispensable in a variety of industries. Whether measuring the level of a liquid in a tank or monitoring the volume of material in a silo, high-level magnetic gauges provide reliable and accurate measurements that help professionals make informed decisions and optimize their operations.

- Understanding the Accuracy of High-Level Magnetic Gauges

In the realm of industrial and scientific applications, the use of high-level magnetic gauges has become increasingly prevalent for measuring the levels of liquids and solids in various types of containers. Understanding the accuracy of these gauges is crucial for ensuring the reliability and efficiency of the processes they are utilized in.

One of the key benefits of high-level magnetic gauges is their ability to provide precise and real-time measurements of the levels of substances in a container. These gauges utilize a magnetic float that moves up and down with the level of the substance being measured. As the float moves, it interacts with a sensor that detects its position, allowing for accurate readings to be displayed on a digital or analog display.

The accuracy of high-level magnetic gauges is dependent on several factors, including the design and construction of the gauge itself, as well as the properties of the substance being measured. The sensitivity of the sensor and the calibration of the gauge also play a crucial role in determining the accuracy of the measurements.

One of the key advantages of high-level magnetic gauges is their ability to provide continuous and reliable level measurements, even in harsh or hazardous environments. These gauges are often used in industries such as chemical processing, oil and gas, and water treatment, where accurate level measurements are essential for ensuring the safety and efficiency of operations.

Another benefit of high-level magnetic gauges is their versatility and ease of installation. These gauges can be easily integrated into existing systems and can be used to measure a wide range of substances, from liquids to powders. This flexibility makes high-level magnetic gauges a cost-effective and practical solution for a variety of applications.

In conclusion, the accuracy and benefits of high-level magnetic gauges make them a valuable tool for measuring levels of substances in industrial and scientific settings. By understanding how these gauges work and the factors that impact their accuracy, users can ensure that they are using the most effective and reliable measurement tools for their specific needs. Whether used in chemical processing plants, oil refineries, or water treatment facilities, high-level magnetic gauges offer a precise and efficient solution for monitoring and controlling levels of substances in containers.

- Benefits of Implementing High-Level Magnetic Gauges

High-level magnetic gauges are revolutionizing the way industries measure and monitor liquid levels. These advanced instruments offer a plethora of benefits that make them a popular choice for businesses across various sectors. In this article, we will delve deeper into the accuracy and advantages of implementing high-level magnetic gauges in your operations.

Accurate measurement is crucial in industries such as oil and gas, chemical processing, and water treatment. High-level magnetic gauges use magnetic fields to accurately detect the level of liquid in tanks or vessels. This technology eliminates the need for physical contact with the liquid, reducing the risk of contamination and ensuring precise measurements.

One of the key benefits of high-level magnetic gauges is their versatility. These instruments can be used in a wide range of applications, from small storage tanks to large industrial vessels. They can also be customized to suit specific requirements, making them a flexible and cost-effective solution for businesses of all sizes.

In addition to accuracy and versatility, high-level magnetic gauges offer real-time monitoring capabilities. This means that operators can track liquid levels continuously and make informed decisions to optimize processes and prevent spills or leaks. With the ability to set alarms and alerts, these gauges help enhance safety and efficiency in industrial settings.

Furthermore, high-level magnetic gauges are durable and low maintenance, making them a reliable long-term investment. Unlike traditional level measurement devices that can be prone to mechanical failure or corrosion, magnetic gauges are built to withstand harsh conditions and provide years of reliable service.

Another advantage of high-level magnetic gauges is their ease of installation. These instruments can be quickly and easily mounted on tanks or vessels, reducing downtime and minimizing disruption to operations. Additionally, they require minimal calibration and upkeep, saving time and resources for businesses.

Overall, the implementation of high-level magnetic gauges offers numerous benefits, including accuracy, versatility, real-time monitoring, durability, and ease of installation. These advanced instruments provide a cost-effective solution for industries looking to improve their level measurement processes and enhance operational efficiency.

To conclude, high-level magnetic gauges are a game-changer in the world of level measurement. Their advanced technology, coupled with a myriad of benefits, make them an indispensable tool for industries seeking reliable and accurate liquid level monitoring. By investing in high-level magnetic gauges, businesses can improve safety, efficiency, and productivity in their operations.

- Applications of High-Level Magnetic Gauges in Various Industries

High-level magnetic gauges have revolutionized the way industries monitor and measure liquid levels in various processes. These advanced gauges utilize magnetic force to precisely determine the level of a liquid in a tank or vessel. In this article, we will explore the accuracy and benefits of high-level magnetic gauges, as well as their applications in different industries.

One of the key advantages of high-level magnetic gauges is their exceptional accuracy. These gauges are highly precise and provide real-time data on liquid levels, allowing industries to monitor their processes with utmost reliability. The magnetic field technology used in these gauges ensures that the measurements are consistently accurate, even in challenging environmental conditions. This level of accuracy is crucial in industries where precise liquid level monitoring is essential for safety and efficiency.

High-level magnetic gauges offer a range of benefits to industries, including improved efficiency, cost savings, and increased productivity. By providing accurate and reliable data on liquid levels, these gauges help companies optimize their processes and prevent costly errors. With real-time monitoring capabilities, industries can make informed decisions and quickly respond to fluctuations in liquid levels. This proactive approach to monitoring can minimize downtime and maximize productivity, ultimately leading to increased profitability.

The applications of high-level magnetic gauges are diverse and widespread across different industries. In the oil and gas sector, these gauges are used to monitor the level of crude oil in storage tanks and ensure proper inventory management. In chemical processing plants, high-level magnetic gauges help maintain precise levels of various liquids, preventing overflows or shortages that could lead to safety hazards. The food and beverage industry relies on these gauges to monitor the levels of ingredients in storage tanks and ensure consistent product quality.

High-level magnetic gauges are also commonly used in pharmaceutical manufacturing, where accurate level monitoring is critical for maintaining product integrity and meeting regulatory standards. In the water and wastewater treatment industry, these gauges play a vital role in monitoring the levels of chemicals and wastewater in treatment tanks, ensuring efficient and effective treatment processes. In power plants, high-level magnetic gauges are used to monitor the levels of cooling water and fuel in storage tanks, helping to optimize energy production and reduce environmental impact.

In conclusion, high-level magnetic gauges have proven to be invaluable tools for industries looking to improve their liquid level monitoring processes. With their exceptional accuracy, reliability, and versatility, these gauges offer a range of benefits and applications across various industries. By investing in high-level magnetic gauges, companies can ensure optimal performance, safety, and efficiency in their operations.

- Enhancing Processes with High-Level Magnetic Gauges

In today's technological landscape, precision and accuracy are paramount in ensuring optimal performance and efficiency in various industries. One tool that has been instrumental in enhancing processes is the high-level magnetic gauge. This innovative device has revolutionized the way measurements are taken, providing an unprecedented level of accuracy and reliability in a wide range of applications.

High-level magnetic gauges are sophisticated instruments that utilize magnetic fields to gauge the level of various substances in tanks or containers. These gauges offer a level of precision that far surpasses traditional measuring methods, making them ideal for industries where accurate measurements are critical, such as the chemical, pharmaceutical, and food processing industries.

One of the key benefits of high-level magnetic gauges is their ability to provide real-time data on the level of a substance in a tank. This real-time monitoring ensures that operators can take immediate action if levels deviate from the desired range, preventing costly spills or overflows. Additionally, the high level of accuracy provided by these gauges minimizes the risk of errors in measurement, leading to increased efficiency and productivity.

Furthermore, high-level magnetic gauges are incredibly versatile and can be customized to suit specific industry requirements. With a wide range of options available, including different materials, mounting styles, and measurement ranges, these gauges can be tailored to fit virtually any application. This adaptability makes high-level magnetic gauges a valuable tool for industries with unique or challenging measurement needs.

In addition to their accuracy and versatility, high-level magnetic gauges offer several other benefits that make them an indispensable tool for modern industries. These gauges are low maintenance and easy to install, requiring minimal downtime for calibration or repairs. Their durable construction ensures long-term reliability, even in harsh operating conditions.

Overall, high-level magnetic gauges are a game-changer for industries that depend on precise measurements for optimal performance. By enhancing processes with their high level of accuracy and reliability, these gauges provide a valuable tool for improving efficiency, productivity, and safety in a wide range of applications. With their real-time monitoring capabilities and customization options, high-level magnetic gauges are sure to remain a staple in industries that prioritize precision and quality control.

Conclusion

In conclusion, the exploration of the accuracy and benefits of a high-level magnetic gauge has shown significant promise in various industries. With its precise measurements and reliable data collection capabilities, this technology has the potential to revolutionize how businesses monitor and track their processes. By investing in a high-level magnetic gauge, companies can ensure efficient operations, improved product quality, and ultimately, increased profitability. As technology continues to advance, it is crucial for companies to stay ahead of the curve and adopt innovative tools like high-level magnetic gauges to stay competitive in today's fast-paced market.